Our production possibilities range from prototype construction to small batch production and series production.

With distinctive customer orientation, many years of experience as well as professional consulting and conception, we offer an all-round service in the field of electronics manufacturing.

In addition to the latest SMD production technology, we manufacture using conventional THT (through-hole technology), for example for special designs, and also offer complete device production and control cabinet construction.

The latest technology in electronics production

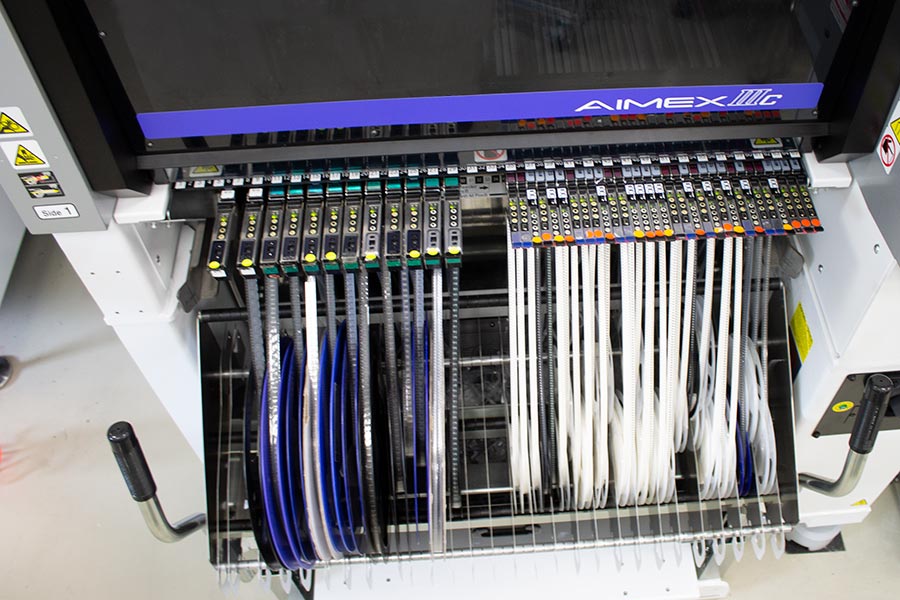

The heart of our modern SMD line are the Fuji AIMEX IIIc placement machines, which are characterized by short changeover times and a very high production quality. Unlike pure EMS providers, small or frequently changing batch sizes are also welcome. For this reason, small series production is also possible at HESCH.

Reliable and on-time production is supported by international component procurement, an end-to-end ERP logistics system and ISO 9001:2015 quality management.

Are you looking for a partner for electronics manufacturing?

Write to us or call us right away:

+49 5032 - 9535 0

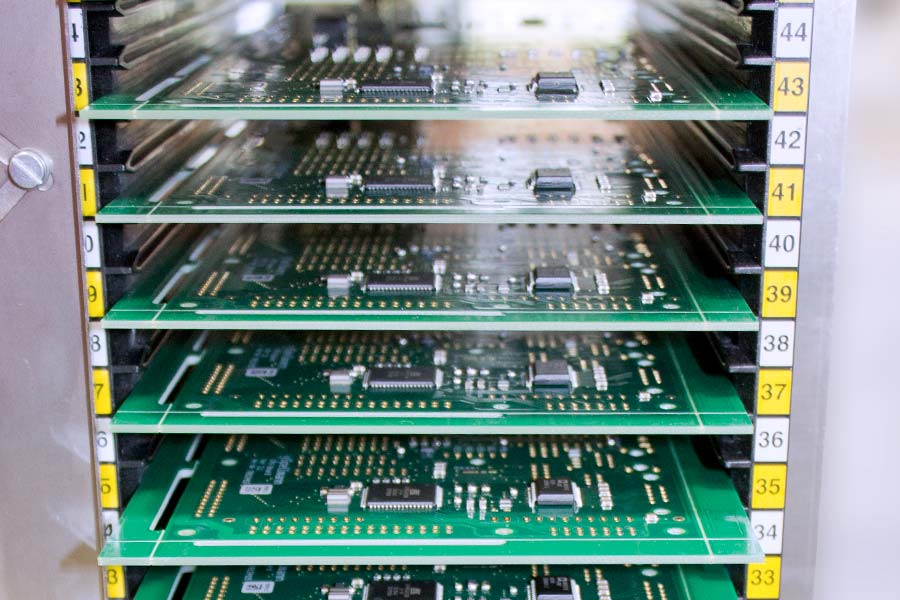

Quality assurance through output testing

Already during the assembly of the circuit boards, several types of checks prevent the occurrence of errors. In addition, all printed circuit boards in electronics production are subjected to an automatic output inspection, or AOI for short (automatic optical inspection). The finished devices are also tested for proper function using appropriate test equipment and endurance tests. The result: Highest quality

Our services

Electronics production according to national and international standards

Prototype construction, small batch production, series production

Serial number management for each finished product

International purchasing for optimized component supply

Storage service for your products

Reflow soldering system with flexible profile manager

High heat output, maximum flexibility due to twelve heating zones and individual soldering profiles enable best soldering results

The soldering profiles are stored and are available at any time

Of course we solder lead-free according to RoHS (Restriction of (the use of certain) Hazardous Substances).

Mounting (push-through mounting)

THT (through-hole technology) components are wired components which are inserted through the openings in the printed circuit board. This is done conventionally at HESCH. The combination of SMD (Surface mounted Device) and THT assembly is a frequent necessity and is also called mixed assembly. The advantage of THT mounting is the possibility of processing very large components and special designs such as power supply units. Our well-trained and experienced team in electronics manufacturing guarantees the highest quality.

Automatic electronics production

With 260 feeder slots, the automatic placement machines from industry leader Fuji offer appropriate feeders for almost every component and component shape. Whether rolls, trays or even bars – we are prepared for (almost) every component.

Would you like more information?

Give us a call at:

+49 5032 9535-0

or write us via the contact form.