Multifunction controller – one for all!

Programmable logic controllers are, in a sense, the brains of the modern factory. But not all tasks require a full-fledged PLC. With the multifunction controller, HESCH has therefore developed a modern controller platform for industrial processes that closes the gap between a standard controller and the PLC.

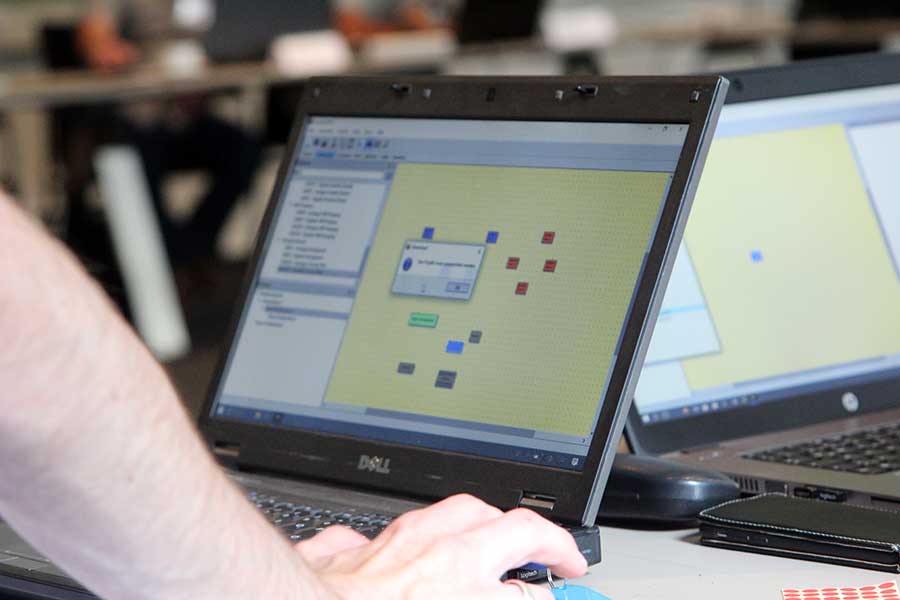

Your process engineers think in function blocks – so does the HESCH multifunction controller! With the HESCH multifunction controller, your process engineer can map complex process sequences intuitively, quickly and completely without programming knowledge.

Reduce costs – preserve know-how!

Up to now, the usual way of finding an individual solution for temperature regulation and sequence control has usually been via programmable logic controllers, also known as PLCs.

An external PLC programmer must be consulted for each adaptation. This often results in high costs, as the average daily rates are around 800 to 1000 euros. In addition, trained PLC programmers usually do not have the necessary process knowledge. Therefore, your process engineer has to explain the process in detail and thus reveals your know-how to outsiders. Subsequently, an elaborate evaluation is necessary. Again and again, this leads to a loss of communication between technicians and programmers. Even after commissioning, a PLC programmer must be consulted for each adjustment.

Promote your internal know-how instead of transferring it to the outside via PLC programmers. With the HE 5697 MFC, every process engineer is able to create, optimize and monitor complex process controls in a very short time.

The multifunction controller offers the solution!

The multi-function controller from HESCH breaks through these cost drivers and enables your process engineers to implement your desired processes without any programming knowledge. These can be adapted, optimized and further developed at any time in a cost-neutral manner.