Differential pressure: Small difference – big effect

Differential pressure regulators and differential pressure gauges are important instruments for measuring and regulating differential pressure in industrial applications. They are indispensable for reducing energy costs, increasing efficiency and improving the quality of processes.

HESCH offers a wide range of high-quality products and individual solutions to meet the requirements of different applications.

Ranges of application

Differential pressure regulators and differential pressure gauges are mostly used in the following applications:

- dust extraction systems

- ventilation and air conditioning systems

- filter monitoring

- pressure and volume flow monitoring

- Laboratory and medical technology

Take a look at our product overview now

► Differential pressure measurement technology

now on

Accessories and software

The exact detection and control of differential pressure plays an important role in many areas of industry, but also in building automation. The differential pressure gauges from HESCH do not just control the condition of filter systems, but also monitor the volume flows of ventilation and air conditioning systems.

Precise adjustment is the prerequisite here for effective moisture and heat protection and a healthy indoor climate. For this purpose, we offer the HE 5411 differential pressure transmitter an excellent and proven product – but also for space-saving use in the control cabinet, we offer the differential pressure transmitter for standard rails – HE 5410 a suitable solution.

Different types

There are several types of differential pressure regulators and differential pressure gauges that can be selected depending on the application and measurement range – the most common include:

Differential pressure gauges with and without indication / display

differential pressure transmitter with analogue or digital output signal

differential pressure transmitters for monitoring high pressure and low pressure applications

Differential pressure regulators for dust extraction systems

Differential pressure regulators are particularly important in dust extraction systems, because compressed air is one of the most expensive forms of energy. Resource efficiency and sustainability are more than important in nowadays, not least because of the energy crisis and the resulting rise in electricity prices.

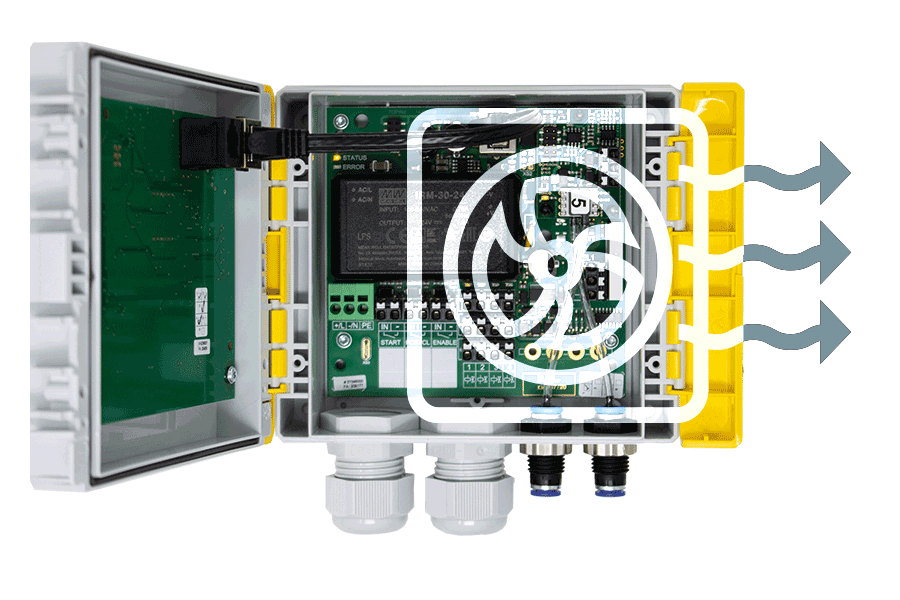

Differential pressure regulators from HESCH control the cleaning of the filter elements depending on the measured differential pressure between the raw gas and clean gas sides.

Compared to the still widespread time-controlled cleaning, this method reduces the energy requirement and thus the total costs for a filter system, because the filter elements are only cleaned as required and adapted to the filter saturation. This also extends the filter service life, as the filter elements are protected and excessive stress due to compressed air shocks is avoided.

The differential pressure regulation also improves the cleaning performance of the entire filter system. The helpful filter cake can be formed and even the finest dust particles are filtered out of the air.

Advantages of differential pressure regulated cleaning

Energy savings through demand-optimized cleaning and thus reduction of compressed air requirements

Prolongation of the filter service life by reducing the number of compressed air shocks

Increasing the cleaning capacity of the filtering equipment

Energy savings through the use of differential pressure regulators + differential pressure transmitters

HESCH’s robust systems are a useful addition to many industrial plants, helping companies to increase efficiency and reduce energy costs.

Furthermore, the use in explosive environments of ATEX zone 2 and 22 is possible.

As OEM partner we supply the differential pressure regulators and differential pressure measuring transducers with individual front foil designs on request, which perfectly match your own brand.

Further high-tech products from HESCH for measuring – controlling – regulating can be found in the area of MCR technology.

How can we help you?

Call us +495032 9535-0

or write us a message.