HESCH offers a wide range of solenoid valve controls for the optimum operation and control of dust extraction systems.

The cleaning of fabric filters in industrial dust collection systems must always be reliable and efficient for the operator in order to comply with the legal requirements for emission limits and to protect the health of employees. Many dusts are hazardous to health, even toxic or explosive, and harm people and the environment.

Read more about environmentally friendly valve controls >

All HESCH valve and filter controls are designed for 24 V DC solenoid valves and feature

Single valve test

Cyclic cleaning

Post-cleaning function

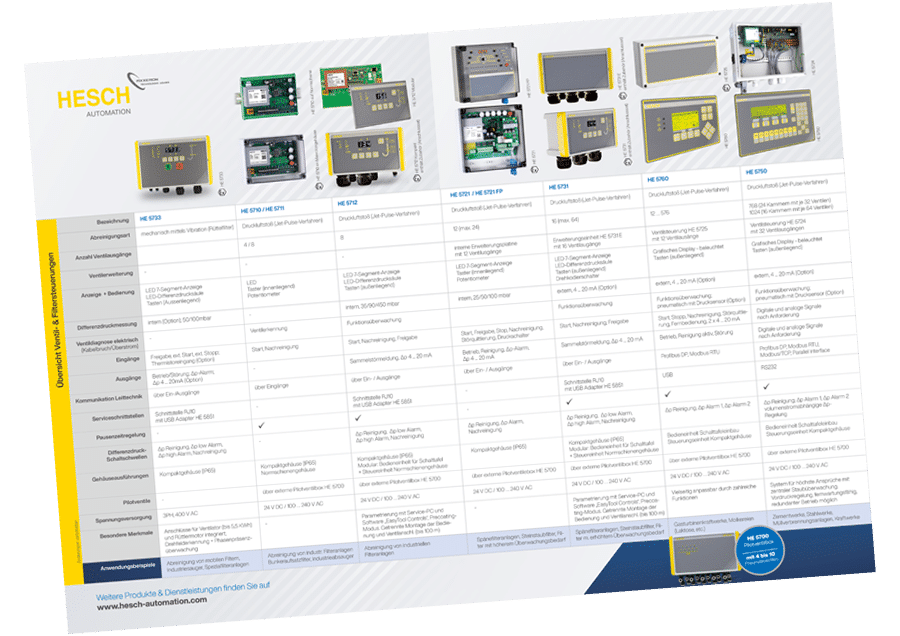

A list of HESCH valve and filter controls in comparison can be found in the

product overview

.

Showing all 16 results

-

Valve control filter control

Valve control – HE 5710 (housing)

4 valve outputs ✓ATEX Zone 22 approval

-

Valve control filter control

Valve control – HE 5711 (housing)

8 valve outputs ✓ATEX Zone 22 approval

-

Valve control filter control

Valve control – HE 5712 (compact)

8 valve outputs ✓internal differential pressure sensor

-

Valve control filter control

Valve control – HE 5712 (modular)

8 valve outputs ✓internal differential pressure sensor

-

Valve control filter control

Shaker filter controller – HE 5733

for industrial shaker filter systems

Software and accessories

Environmentally friendly filter control

Valve control systems from HESCH make a major contribution to sustainable resource efficiencyhere through the

Reduction of dust emissions

Reduction of the energy requirement

Extension of the filter life

Efficiency increase of the filter system

Valve controls for all cases

Depending on the size of the dedusting plant, very different requirements are placed on the process control. In this way, we supply the right valve control for every area of application – from the low-cost small control for industrial vacuum cleaners or bunker top filters to the professional cleaning control for large industrial filter systems, such as those used in cement works, power stations and waste incineration plants worldwide.

Effective control – intelligent savings

In particular, the differential pressure-dependent cleaning of dust filters prevents the over-cleaning of filter media and thus has a significant influence on the filter performance and the overall costs of the system. Compressed air is an expensive medium. Reason enough to contact a professional for valve control already when planning a filter system.

The use of an intelligent valve control is equally useful for new plants as well as for increasing the performance of existing fabric filter plants.

Thanks to the modular design, you can assemble your valve control system to fit exactly.

with or without integrated differential pressure sensor

for small to medium pressures from ±2.5 mbar to ± 1000 mbar

for controlling 1-1024 valves

You can find a list of our valve and filter controllers in comparison in the > product overview

What functions does a valve control system from HESCH offer?

Cyclic cleaning and re-cleaning

Time-controlled or differential pressure-controlled cleaning of the fabric filter

Break time regulation

Valve monitoring for overcurrent (short circuit) and interruption (cable break)

Precoating mode

Multiple pulse

Menu-less and language-independent user interface

Parameterization with service PC and EasyTool Controls software (available as accessory)

Use in potentially explosive atmospheres of ATEX zone 22 (explosive dusts)

Display of the differential pressure / actuated valve

Configurable inputs and outputs

LED indicators for operation, switching thresholds, alarm messages and parameterization

Areas of application for valve control

- Mobile industrial vacuum cleaner

- Stationary industrial vacuum cleaners

- Bunker top filter

- Silo attachment filter

- Transfer filter

- Welding smoke filter

- Chip filter

- Stone dust filter

- Filters with high monitoring requirements e.g.

- Cement plants

- Steel mills

- Waste incineration plants

- Power plants / coal-fired power plants

- Lime works

- Sewage sludge incineration plants

- Crude steel production

With over 47 years of experience in the development and manufacture of solenoid valve controls for industrial dedusting technology, we are your professional partner for everything from simple control tasks to special solutions in small batches.

We develop and produce precisely for your individual requirements.

You tell us your requirements and we will supply you with the right system.

As a ready-made solution in the desired format: from compact housings to control units in <a href="https://www.hesch-automation.com/en/services/switch-cabinet-construction/">control cabinets</a>.

Put your product in the right light!

As an OEM partner of well-known national and international filter manufacturers and manufacturers of ventilation systems, we also offer the valve control as a fire label. Thus, the design of the filter control is adapted to the own brand and integrates perfectly into the overall picture of the plant.

Many things are possible – Talk to us.

Call us

We are happy to help you!

+49 5032 9535-0

or write us directly via the contact form.