Valve control in compact housing for use in ATEX Zone 22

The basic unit HE 5731 enables the time or differential pressure dependent control of 16 solenoid valves in dedusting systems.

The control unit HE 5731

- Menu- and programming-free parameterization

- Operation via membrane keys

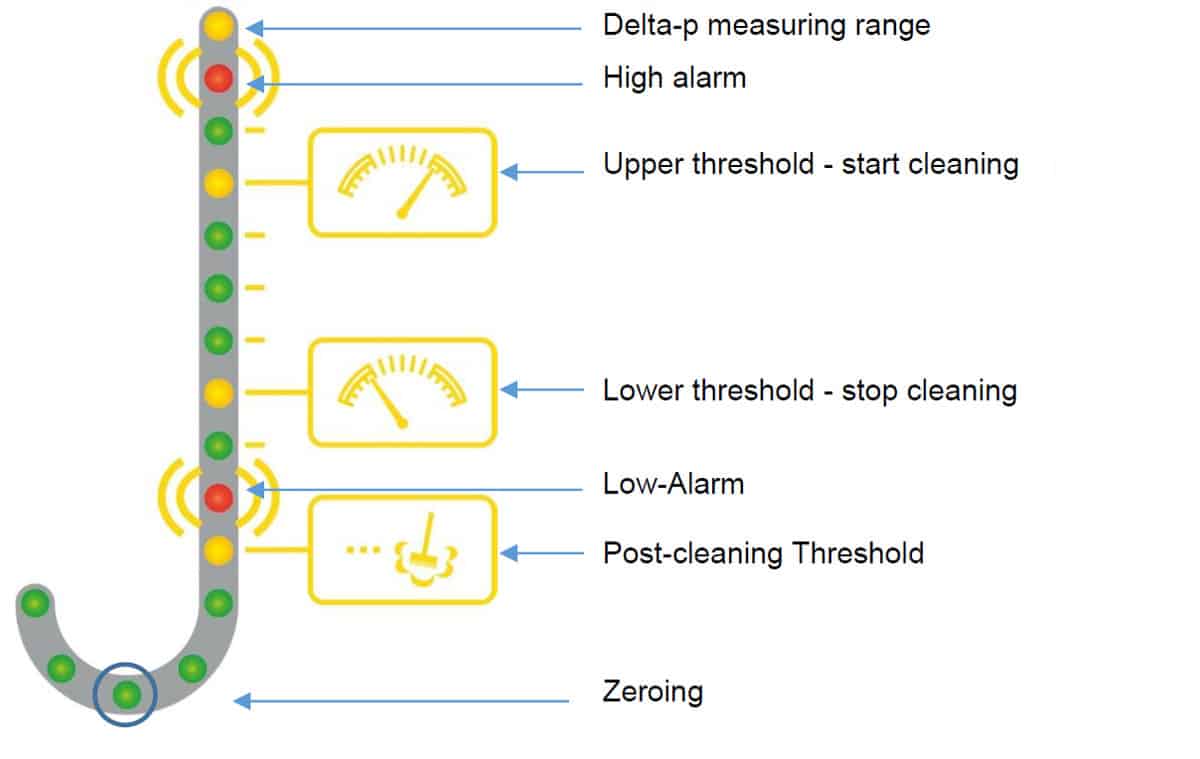

- Intuitive operation due to clear symbols and differential pressure level display

- Three-digit digital display

- Screwless connection technology

- Device version also available as time control

Modular expandable

With three extension units, 64 valves can be controlled. The valves are activated sequentially and monitored for overcurrent and interruption.

Intuitive operation

The language-independent symbol labelling enables the control system to be used worldwide.

- Clear status display with LEDs

- Simple operation without complicated menu structures

External differential pressure measurement

The differential pressure is measured externally and transmitted as a 4…20 mA signal to the higher-level controller (does not apply to devices with pure time control). The signal can be connected to the master as well as to one of the extension units. Furthermore, it is possible to connect the 4…20 mA signal e.g. to an external display unit. For this purpose, the indicator is connected in series with a differential pressure transmitter(e.g. HE 5409) according to the wiring diagram. If galvanic isolation is necessary, an isolation amplifier (e.g. HE 501/HE 502) should be used.

Convenient parameterization

The control system can be parameterized via the membrane keypad or optionally with the EasyTool Controls software. With EasyTool Controls, parameter data sets can be transferred to the controller easily and quickly. This is particularly convenient when a number of controllers have to be recorded with the same data sets.

Practical: Flexible mounting for reduced cabling

The modular concept of the HE 5731 allows the control unit to be mounted separately from the operating unit. The control unit can be mounted up to 100 meters away from the control unit so that the control unit is in the user’s field of vision. This means he always has the status display in view and can react quickly if necessary. The control unit with the valve connections remains close to the valves, which significantly reduces the amount of cabling required.

The separately available connection set with matching cable glands and the pre-assembled cables with valve plugs in various lengths are a useful addition to the control system.